T2180 Deep-hole drilling and boring machine

Keywords:

Deep-hole drilling and boring machine

- Product Description

-

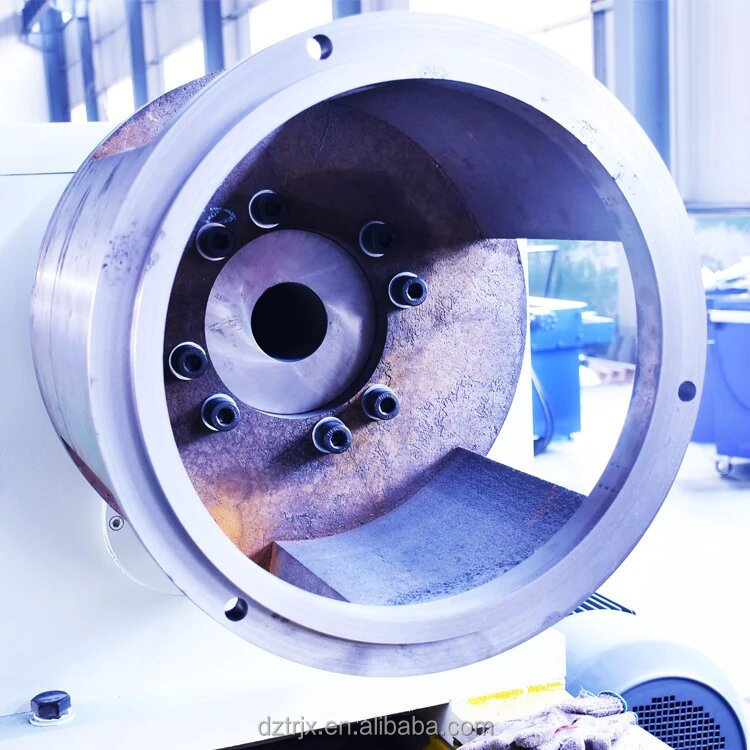

This machine is a deep-hole equipment specially used for internal hole processing of heavy workpieces. This machine tool can complete the drilling, boring, expanding, rolling, and nesting of inner holes.

First, the basic process performance of the machine tool:

This machine is a deep-hole equipment specially used for internal hole processing of heavy workpieces. This machine tool can complete the drilling, boring, expanding, rolling, and nesting of inner holes. The boring bar uses cutting fluid to discharge cutting fluid and iron chips to the bedside. According to user requirements, the machine tool can be equipped with a drill (boring) rod box to increase the drilling function. The BTA chip removal process is used for drilling. The workpiece can be rotated at low speed and the tool can be reciprocated at high speed to improve processing efficiency. Zh

Heavy-duty deep-hole boring machine can process the inner hole diameter of the workpiece up to φ800mm, and the length of the workpiece can reach 16m. Zh

Processing accuracy of machine tools:

During rough boring: hole diameter accuracy IT9-10. Surface roughness: Ra6.3. Zh

When fine boring: hole diameter accuracy IT8-9. Surface roughness: Ra3.2. Zh

During rolling: Aperture accuracy IT8-9. Surface roughness: Ra0.4 or more. Zh

Straightness of processed hole: ≦ 0.15 / 1000mm. Zh

Exit deviation of the machined hole: ≦ 0.5 / 1000mm. Zh

Processing efficiency of machine tools:

Cutting speed: determined according to the tool structure, material and workpiece material, generally 50-100m / min. Zh

Feed rate: determined according to the conditions of the workpiece and the process, generally 10-100mm / min. Zh

Maximum machining allowance when boring: Determined according to the tool structure, material and workpiece conditions, generally not more than 30mm.

Second, the main technical specifications and parameters of machine tools:

Specifications

Parameter

TK2180

Boring diameter range

Φ100-Φ800mm

Drilling diameter range

Φ60-Φ120mm

Processing depth range

1-16m(1m per interval)

Spindle center heigh

800mm 1000mm

Headstock spindle diameter

Φ100mm

Taper hole at the front end of spindle

Φ120mm,1:20

Spindle speed range and number of stages

3-120r/min Stepless

Spindle motor

55kw

Feed speed range

0.5-450mm/min Third gear stepless

Pallet fast moving speed

2m/min

Working clamping diameter range

400~1200mm

Spindle bore of drill box (optional)

100mm

Spindle motor

45kw/55KW

Taper hole at the front end of main shaft of drill pipe box (optional)

Φ120mm,1:20

Speed range and number of stages of drill pipe main shaft (optional)

16-270r/min Level 12

Feed motor

N=5.5 kw (AC servo)

Pallet fast motor

N=7.5kw

Cooling pump motor

N=5.5 kw, (3groups)

Hydraulic pump motor

N=1.5kw,n=1440r/min

Cooling system rated working pressure

0.36MP

Cooling system flow

300、600、900L/min

Honors

Factory Workshop

Packing & Delivery

Customer Visit

FAQ

Related Products

Newly Released Products