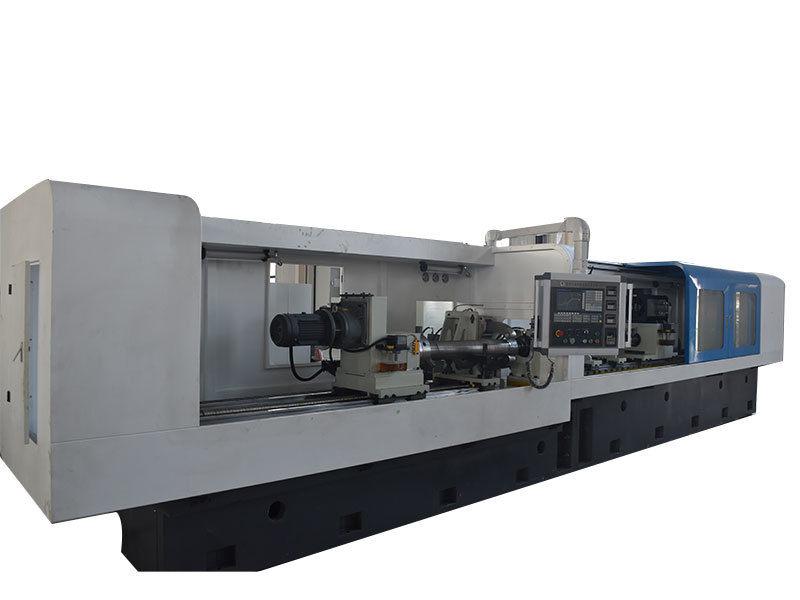

Deep-hole drilling machine ZK2103

Keywords:

Deep-hole drilling machine

Classification:

- Product Description

-

Tianrui single-axis CNC deep hole gun drill (ZK2103) is a special deep hole gun machine with high efficiency, high precision and high automation.

Demonstration of the ZK single-axis series of machines

Tianrui single-axis CNC deep hole gun drill (ZK2103) is a special deep hole gun machine with high efficiency, high precision and high automation. The external chip removal drilling method (gun drilling method) can replace the machining accuracy and surface roughness that generally require drilling, expansion and reaming processes through one continuous drilling. Tianrui single-axis CNC deep hole gun drill is controlled by digital control system, which not only has a single-action function, but also has the function of automatic circulation. Therefore, it is not only suitable for small batch processing, but also especially suitable for large batch production processing requirements. It can not only drill through holes, but also process blind holes or stepped holes, and can also process eccentric holes and oblique oil holes when cooperating with special tooling.

Features of the machine

1. High machining accuracy (≤0.02) and high finish (≤Ra0.8-1.6).

2. The processing efficiency is 20 times that of traditional machine tools.

3. The machine tool is automatically controlled by numerical control program, which is suitable for mass production.

4. The clamping workpiece is simple, the two-cone disc jacking structure is adopted, the positioning accuracy is high, the coaxiality is ≤0.02, and the V-shaped iron clamping can also be used.

Comparison of additive efficacy

The name of the machine

CNC single-axis gun drill

Ordinary lathes

Radial drilling machine

Machine model

ZK2103

CD6140

Z3050

Labor quantity

One person/shift

One person/shift

One person/shift

Workpiece specifications

φ10×2 m

φ10×2 m

φ10×2 m

material

45#

45#

45#

Class yield

20 pcs

1 pc

Cannot be processed

Technical data of ZK single-axis gun drill series

The name of the project

ZK2102 parameters

ZK2103 parameters

Scope of work

Drill diameter range

φ3-φ20mm

φ3-φ20mm

Processing length

500-2000mm

500-2500mm

Drill pipe box spindle parameters

Center height

200mm (can be customized)

200mm (can be customized)

Taper at the front of the spindle

φ40mm 1 :20

φ40mm 1 :20

Spindle variable speed range

30-4000r/min (stepless speed regulation)

30-4000r/min (stepless speed regulation)

Boring bar torque

≥35N.m

≥50N.m

Feed parameters

Feed rate range

5-1000mm/min

5-1000mm/min (stepless)

The pallet moves quickly

2m/min

2m/min

Boring bar feed torque

≥10N.m

≥10N.m

Positioning length

0-2500mm

0-2500mm

The cylindricity of the workpiece is machined

≤0.016/500mm

≤0.016/500mm

Roundness of workpiece machining

≤0.01/100mm

≤0.02/100mm

Motor capacity

Drill pipe motor power

5KW AC servo motor

0.75KW AC servo motor

Hydraulic pump motor power

5.5KW

5.5KW

Feed motor

0.75KW AC servo motor

1.6KW AC servo motor

Numerical control system

SIEMNS KND or user-selectable

Honors

Factory Workshop

Packing & Delivery

Customer Visit

FAQ

Related Products

Newly Released Products