MK1000 Deep hole honing Machine

Keywords:

Deep hole honing Machine

Classification:

- Product Description

-

MK1000 CNC deep hole powerful honing machine is suitable for honing and polishing cylindrical deep hole workpieces, such as various hydraulic oil cylinders, cylinders and other precision pipes. Particularly suitable for honing and polishing workpieces with stepped holes.

MK1000 CNC deep hole powerful honing machine is suitable for honing and polishing cylindrical deep hole workpieces, such as various hydraulic oil cylinders, cylinders and other precision pipes. Particularly suitable for honing and polishing workpieces with stepped holes. Its machining aperture accuracy can reach IT8 ~ IT9 level or above, and the surface roughness can reach Ra0.2-0.4μm. Local honing can be used to correct the taper, ovality and local aperture error of the workpiece. For some cold drawn steel pipes, strong honing can be performed directly.

MK1000 CNC deep hole powerful honing machine is an ideal equipment for high precision and high efficiency deep hole machining. The machine is equipped with SIEMENS or FANUC numerical control system, AC servo motor, and the grinding rod box adopts stepless speed regulation. The honing head is reciprocated with high-precision rack and pinion, which can accurately control the honing position. The linear guide is adopted, which has higher service life and higher accuracy. The honing head is expanded by hydraulic constant pressure, and the honing force of the sand bar is stable to ensure the roundness and cylindricality of the workpiece. The honing pressure can be adjusted as required, and high and low pressure controls can be set to achieve the conversion of rough and fine honing on the console.

Main technical parameters

Project Name

MK800

MK1000

Processing aperture range

Φ100-Φ800mm

Φ300-Φ1000mm

Maximum processing depth

12000mm

Grinding box spindle speed range

10-200r/Min(Stepless)

Range of workpiece clamping diameter

Φ100-Φ1000mm

Φ300-Φ1200mm

Pallet reciprocating speed range

5-40m/Min(Stepless)

Cooling pump flow

200L/Min

Working pressure of grinding head expansion hydraulic system

4MPa

Grinder box main motor power

22kW(AC spindle motor)

Grinding box reciprocating motor

200Nm(AC spindle motor)

Grinding head expansion motor power

3.5kW

Motor power of cooling system

5.5kW

Next

Honors

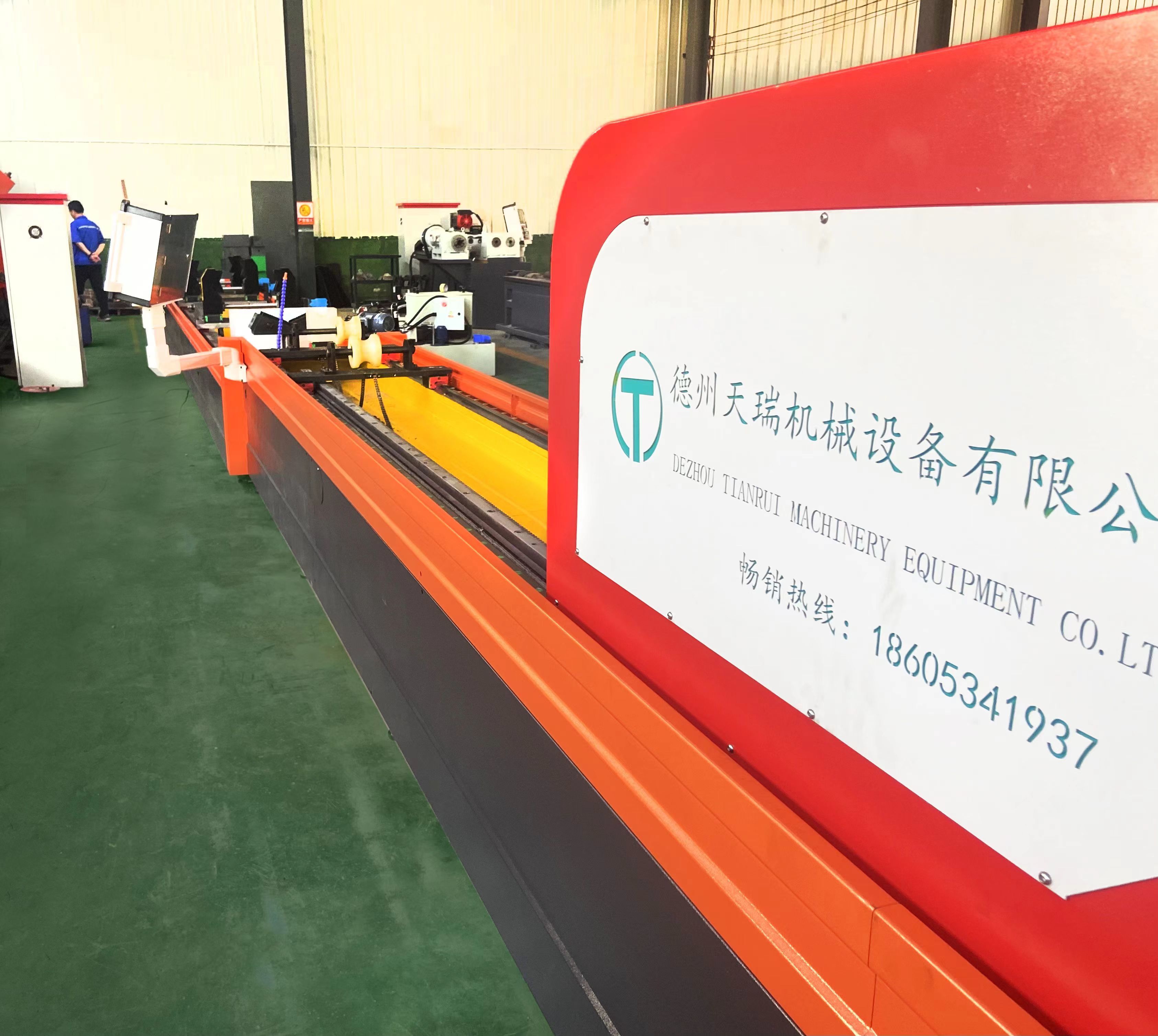

Factory Workshop

Packing & Delivery

Customer Visit

FAQ

Related Products

Newly Released Products