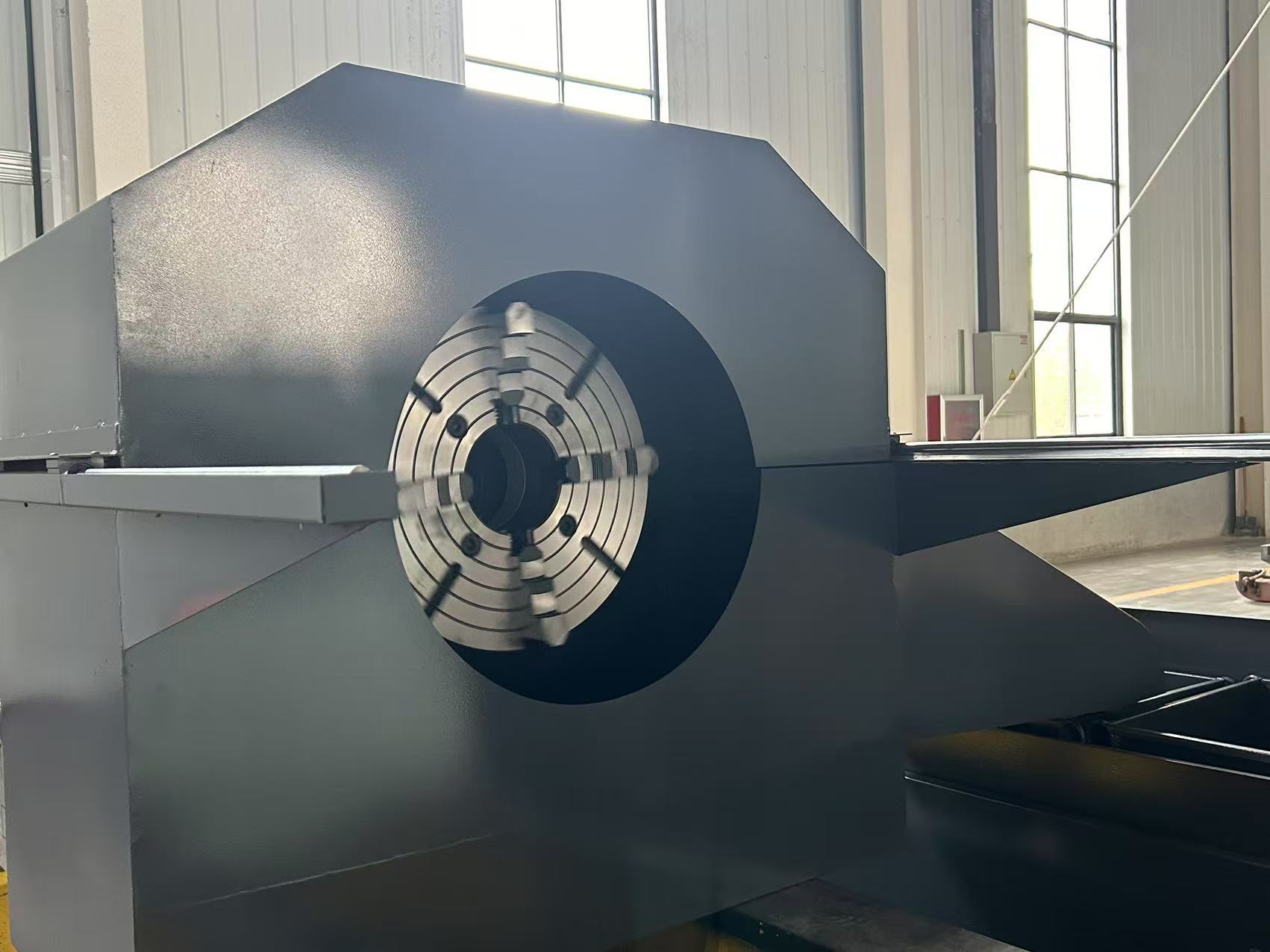

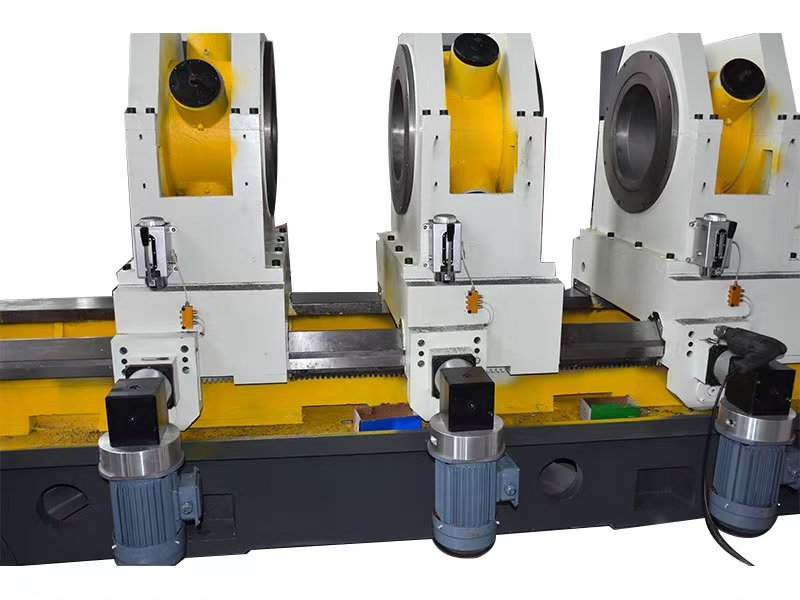

T2150 Deep-hole drilling and boring machine

Keywords:

Deep-hole drilling and boring machine

Classification:

- Product Description

-

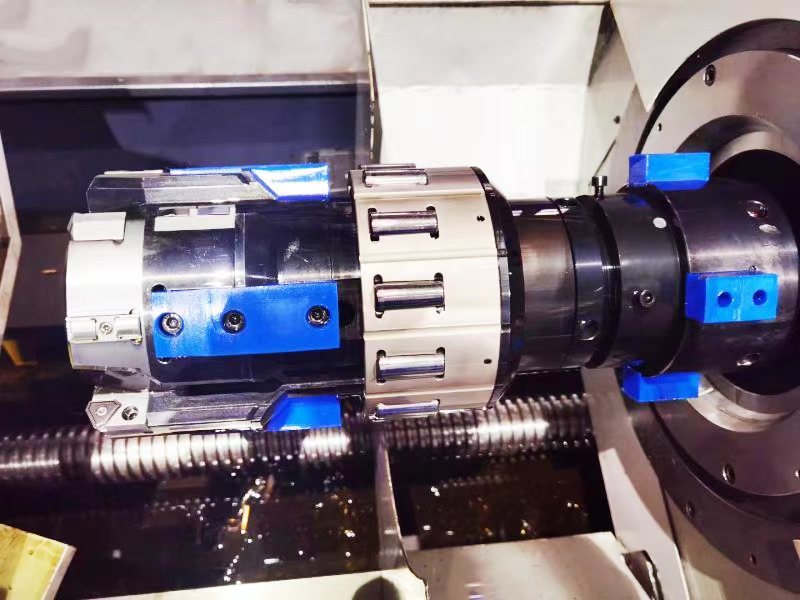

The machine can complete the drilling, boring, nesting and rolling of inner holes. During processing, the process of workpiece rotation, tool feeding, cutting fluid cooling through the oil dispenser (or boring bar) into the cutting area, lubrication, cooling the chip area, and wrapped chips to discharge chips forward.

T2150 Deep hole drilling machine

The basic process performance of the machine tool:1) The machine can complete the drilling, boring, nesting and rolling of inner holes. During processing, the process of workpiece rotation, tool feeding, cutting fluid cooling through the oil dispenser (or boring bar) into the cutting area, lubrication, cooling the chip area, and wrapped chips to discharge chips forward.

2) When drilling, the chip removal process in BTA is adopted. When boring, the process of discharging cutting fluid and cutting chips forward (head end) is adopted.

Machining accuracy of the machine tool:

When drilling: hole diameter accuracy IT9-11. Surface roughness: Ra6.3.During rough boring: hole diameter accuracy IT9-10. Surface roughness: Ra6.3. Zh

When fine boring: hole diameter accuracy IT8-9. Surface roughness: Ra3.2.

During rolling: Aperture accuracy IT8-9. Surface roughness: Ra0.4.

Straightness of processed hole: less than 0.15 / 1000.

The deviation of the outlet of the processing hole: less than 0.2 / 1000

Processing efficiency of machine tools:

Cutting speed: determined according to the tool structure, material and workpiece material, generally 50-100m / min.Feed speed: determined according to the processing conditions, generally 40-100mm / min.

Maximum machining allowance when boring: Determined according to the tool structure, material and workpiece conditions, generally not more than 30mm.

Machine parameters:

Specifications

Parameter

T2150

Boring diameter range

Φ250-Φ500mm

Drilling diameter range

Φ60-Φ120mm

Processing depth range

1-12m(1m per interval)

Working clamping diameter range

300-650mm

Spindle center height

625mm

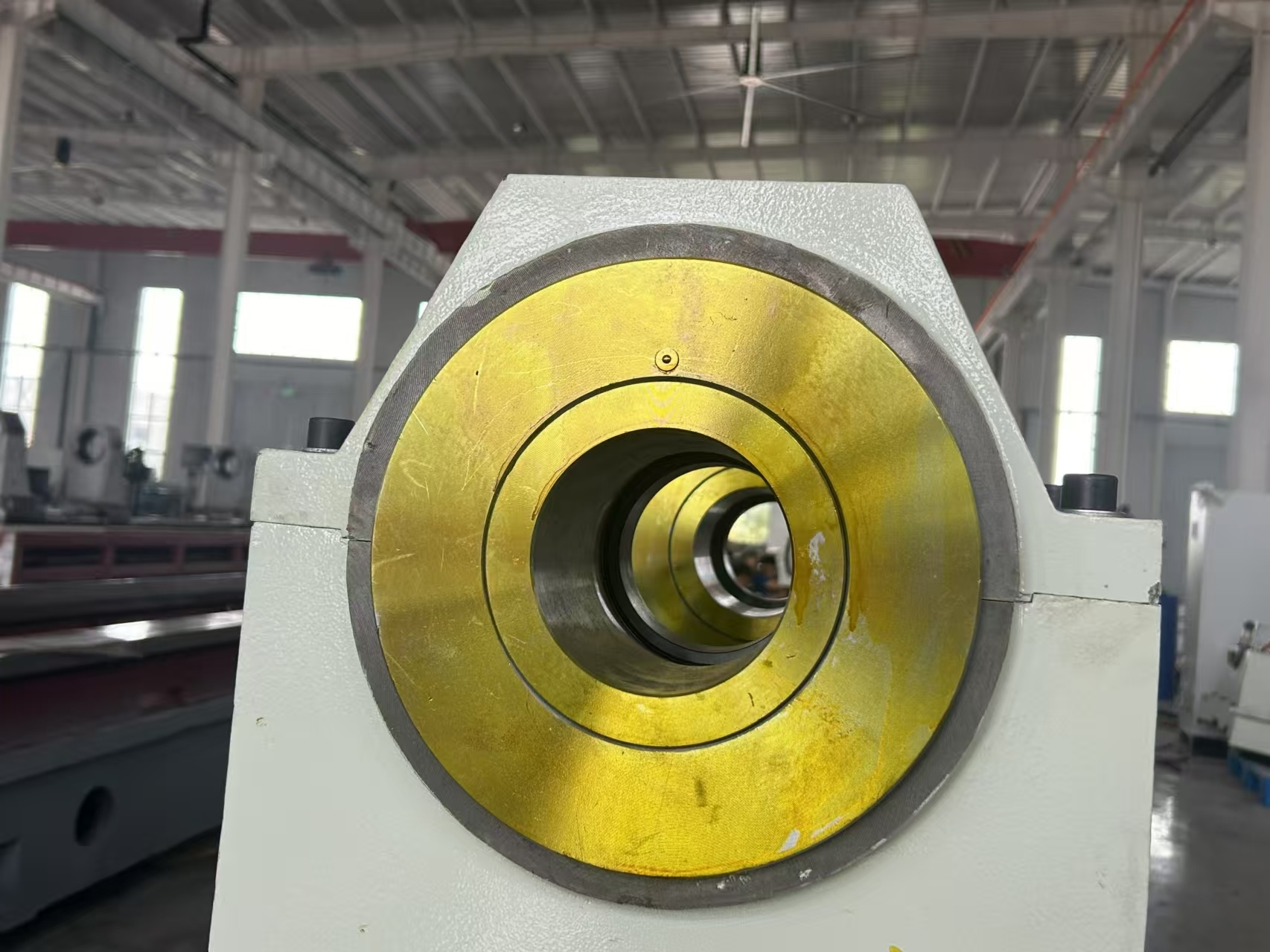

Headstock spindle diameter

Φ130mm

Taper hole at the front end of spindle

140# 1:20

Spindle speed range and number of stages

3.15-315r/min Level 21

Spindle bore of drill box (optional)

75mm

Taper hole at the front end of main shaft of drill pipe box (optional)

Φ85mm,1:20

Speed range and number of stages of drill pipe main shaft (optional)

80-350r/min Level 6

Feed speed range (stepless)

5-1000mm/min

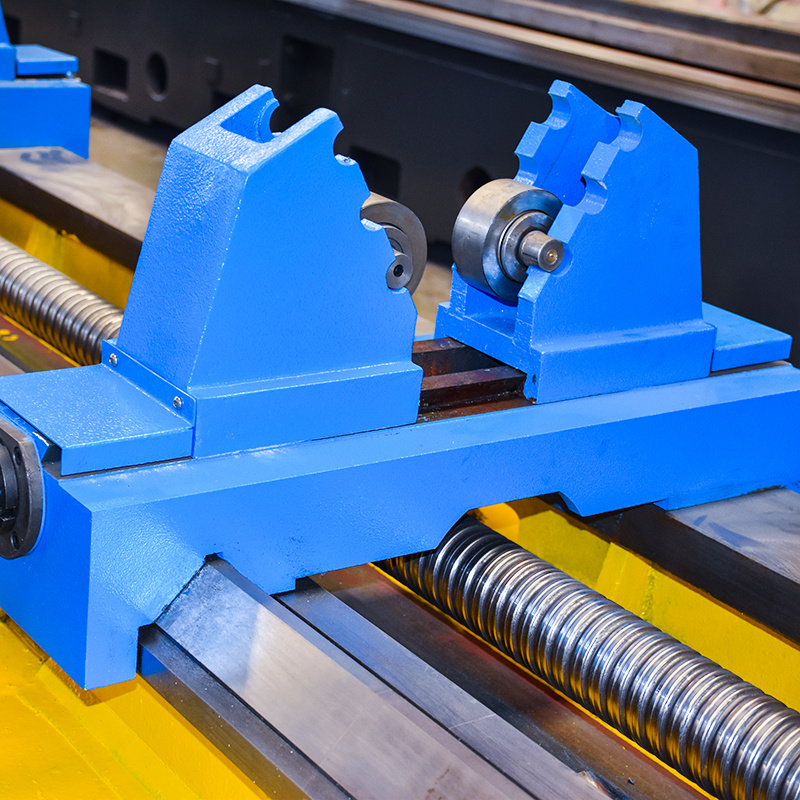

Pallet fast moving speed

2m/min

Spindle motor

N=30kw,n=960r/min

Motor of drill pipe box (optional)

N=22kw,n=1460r/min

Hydraulic pump motor

N=1.5,n=1440r/min

Pallet fast motor

N=3kw,n=2880r/min

Feed motor

N=5.5KW(AC servo)

Cooling pump motor

N=5.5KW,N=1460r/min(3groups)

Cooling system rated working pressure

0.36MP

Cooling system flow

300、600、900L/min

Rated working pressure of hydraulic system

2.5MPa

Axial load of the oil feeder

68KN

Maximum tightening force of oil dispenser on workpiece

20KN

Honors

Factory Workshop

Packing & Delivery

Customer Visit

FAQ

Related Products

Newly Released Products