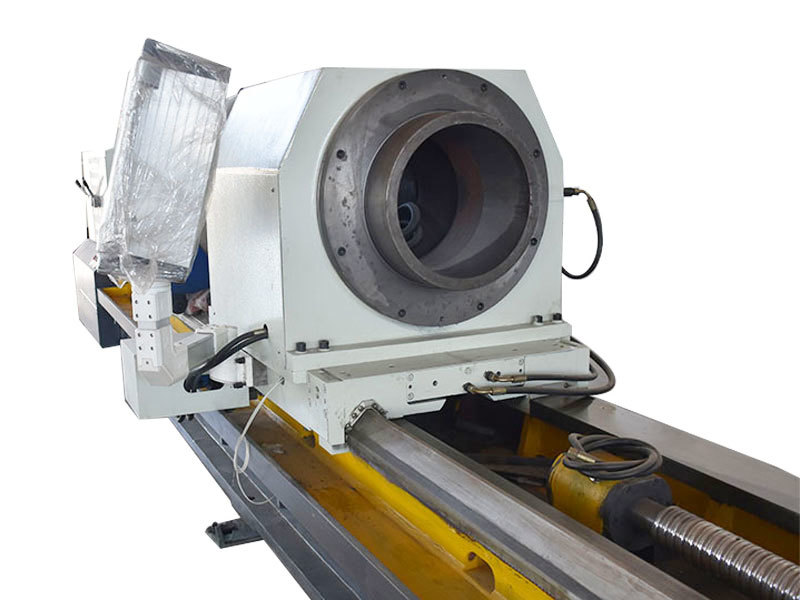

Deep hole drilling and boring machine tools are used in more and more machine tool industries

Release time:

2018-08-03

Deep hole drilling and boring machine tools are receiving more and more attention in more and more machine tool industries. Of course, there are some problems that often occur with deep hole tools. What is the reason? :

1. Production performance

Refers to the productivity. Here is the batch size of deep hole drilling and boring machine tool parts, mainly from the consideration of tool selection and processing costs. For example, the use of special tools in large-scale production may be cost-effective, and in single-piece or small-batch production, The selection criteria are more suitable for some deep-hole drilling and boring machine tools.

2. Machine type

The influence of the NC machine tool used in the machining process on the choice of deep hole drilling and boring machine tool type (drill, turning or milling cutter). High-productivity tools such as high-speed cutting tools and high-feed turning tools can guarantee the rigidity of the workpiece system and the rigidity of the deep-hole drilling and boring machine tool system.

Three. CNC machining program

Different types of deep hole drilling and boring machine tools can be used for different CNC machining solutions. Such as drilling reamer drilling can also be used for drilling and boring machines.

Latest information

Dezhou Tianrui Machinery Equipment Co., Ltd.

2025-01-02